ACDC Dynamics has always strived to be a market leader in offering the widest range of products from ACDC Dynamics supply chain of global leaders. ACDC Dynamics will be introducing the Danfoss VLT® range into its already comprehensive range of Danfoss VACON® variable speed drives. With the introduction of the Danfoss VLT® range of variable speed drives, ACDC Dynamics will be offering the full breadth and depth of a product range needed for any application. Whatever you need, ACDC Dynamics will always get the right drive for your application.

Why choose Danfoss drives for mine and mineral processing environments? |

With our wide range of AC drives and a broad choice of supporting options we can match your specific requirements. The compact enclosures and robust design of our drives with built-in long motor cable capability, innovative heat management and other mine-site-relevant features can help you optimize your panel, switchboard, switchroom or substation design, saving costs and improving your competitive position. |

Intelligent heat management for significantly lower switchroom costs With the increasing use of AC drives to efficiently control equipment on mine sites, the heat loads in | VLT® drives rated 90 kW and higher incorporate an innovative back-channel cooling design. There are separate cooling paths for the power components and control electronics, separated by an IP54 seal. The back-channel cooling removes approximately 85% of the power loss directly through the heatsink, leaving only 15% of the total loss to be dissipated in the switchroom. Although separate cooling paths themselves are not innovative, the innovation in our VLT® drives comes from ensuring they are separated by an IP54 seal and making it easy to duct outside air into and out of the back-channel air path. | |

Reduced heat load in switchrooms. When outside air quality on the mine site is suitable, using the heatsink cooling fans and appropriate mounting and ducting, filtered external air at temperatures up to 50 degrees C can be used to exhaust approximately 85% of the heat loss from the VLT® drive. The heat loss can easily be exhausted directly outside the switchroom with no effect on the switchroom pressurization. The switchroom airconditioningsystem only needs to be sized for the remaining 15% heat losses into the switchroom. | Compact enclosures reduce project costs The compact size of VLT® and VACON® drives, both designed as standard for long motor cables without requiring additional options, often means smaller switchrooms can be built, providing opportunities for significant switchroom cost savings. Ask us, to find out how contractors and mining companies have saved significant project and operating costs through the use of these innovative design features. |

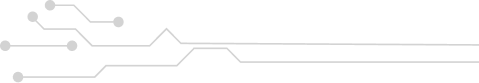

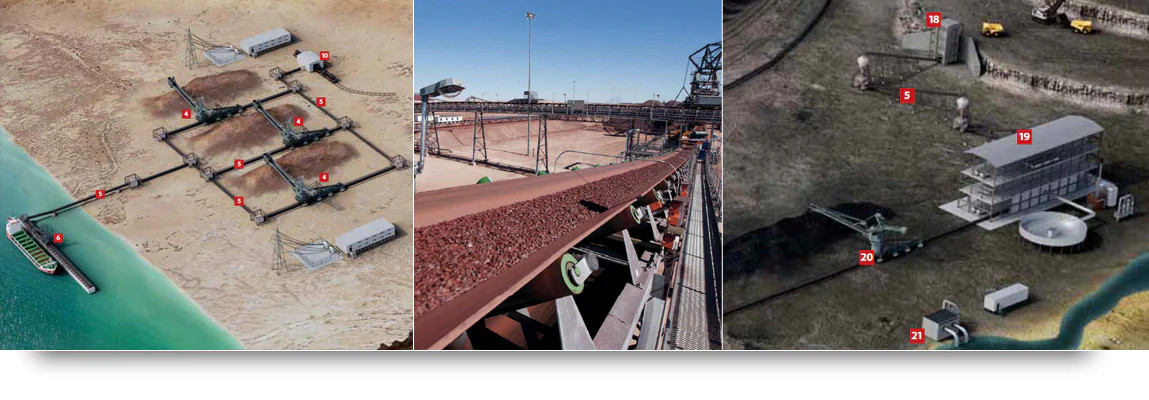

Applications |

No matter how well you have optimized your plant design, there is always a way to drive down costs even further. AC drives are used extensively for just that purpose, extending equipment lifetime, optimizing processes, reducing maintenance and saving energy costs.The mining and minerals industry presents some of the most challenging environments for production. Mine sites, mineral processing facilities and associated stockyards and port facilities are large scale and often in remote locations. |

|

|

Robust mine ventilation | |||||||

Ensuring reliable ventilation of the mine is paramount for the health and safety of workers in the underground mine. This is necessary to ensure particulates from diesel engines are adequately diluted, for example. Ventilation operating costs are often a significant proportion of the total electrical energy costs on site, and being able to ventilate in the most efficient manner saves significant operating costs. AC drives are well recognized to be the most flexible, energy-efficient, low maintenance method for controlling mine ventilation fans. They are used to control the air flow of main ventilation fans on the surface as well as auxiliary ventilation and booster fans underground, and can be easily integrated into Ventilation on Demand (VOD) control systems. Both VLT® and VACON® drives incorporate a number of features that make them especially suitable for mine ventilation fan applications. These ensure reliable operation of the fan even in abnormal operating conditions and the optimum use of energy | |||||||

| |||||||

| |||||||

VLT® Drives | ||||||||

The VLT® AutomationDrive FC 302, VLT® AQUA Drive FC 202 and VLT® HVAC Drive FC 102 are all built on the same modular platform, allowing for highly-customized drives that are mass-produced, fully-tested, and delivered from our factories. | ||||||||

| ||||||||

|

VACON® Drives | ||||||||

The broad range of VACON® NXP drives provides solutions no matter what type of AC drive you need. Air cooled or liquid cooled, wall mounted or floor standing, bottom or top cable entry, 6-pulse, 12-pulse or Active Front End (AFE) are just some of the options possible. | ||||||||

| ||||||||

|

Harmonics Mitigation | ||||||

While AC drives help optimize production, save energy and extend equipment lifetime, they also introduce harmonic currents to the mine-site grid. If not kept under control, these harmonics can affect the performance and reliability of generators and other equipment.. | ||||||

| ||||||

|

A better tomorrow is driven by drives | |||||||

Danfoss Drives is a world leader in variable speed control of electric motors. We offer you unparalleled competitive edge through quality, application-optimized products and a comprehensive range of product lifecycle services. | |||||||

| |||||||

|

Advanced Search

Advanced Search